SUSTAINABILITY

Principle

Ordering Italian Gelateria by phone or online is less harmful to the climate than by making a trip to and from the ice cream parlor. This visit to the ice cream parlor is no longer necessary, because now bicycle delivery couriers can deliver up to 18 ice cream cups at a time on an optimized delivery route while wearing a backpack. World record!!! A decisive contribution to reducing city traffic and CO2 emissions.

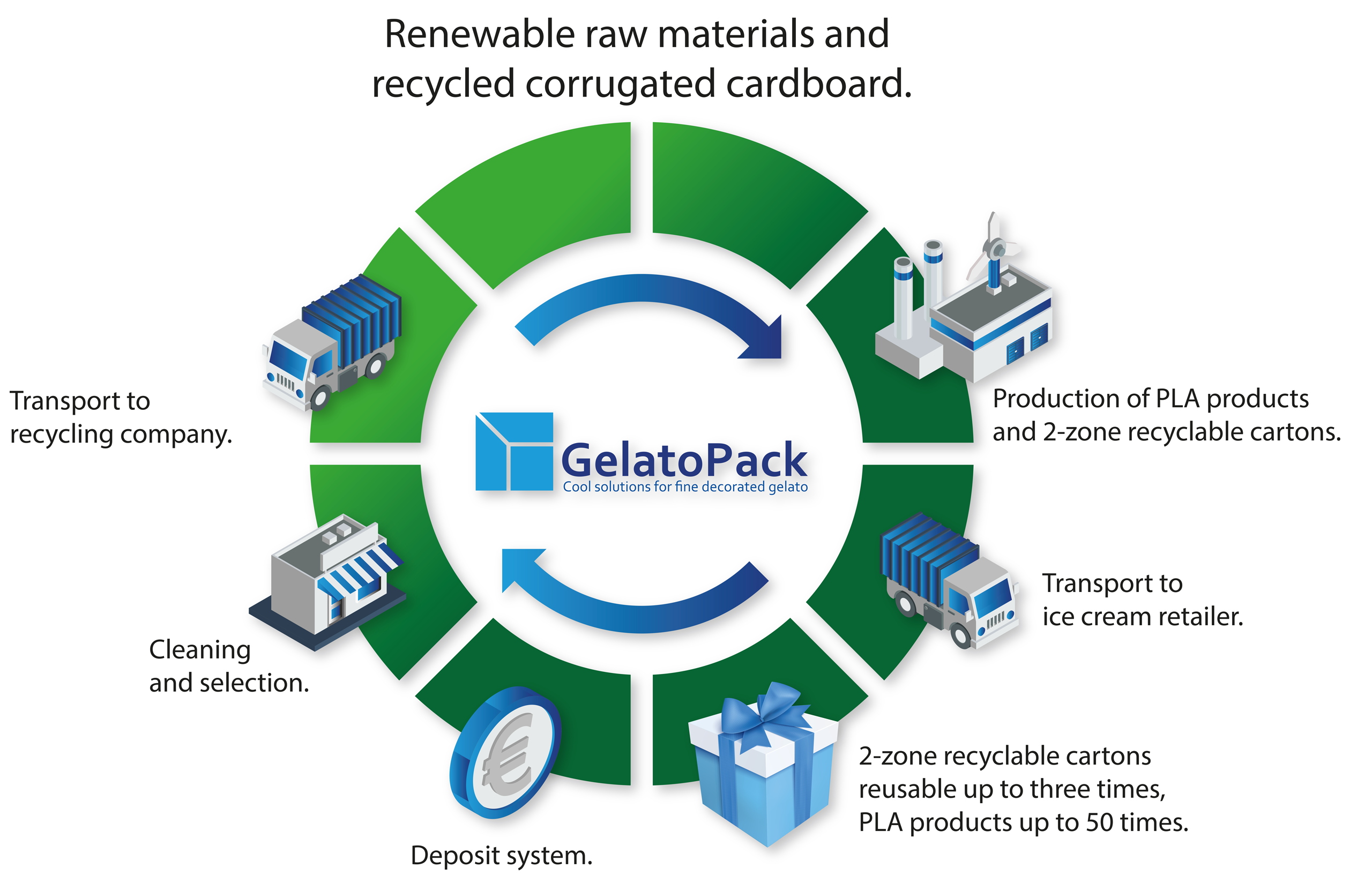

The reusable return system

In addition to the reusable packaging made of FSC100% certified recycled corrugated cardboard, we also look at what happens to the packaging components such as ice cream cups, cold packs batteries etc. after they have been used. After all, billions of environmentally harmful disposable plastic and cardboard packaging items pass over the counter every year. These usually end up in plastic waste or wastepaper containers. This type of packaging pollutes our rivers, lakes, and oceans.

Hygiene concept

The hygiene of the reusable carton with all its inner components, is of utmost importance. The deposit cartons, cold packs and ice cream cups returned by the customer or delivery service are checked to ensure they are intact. Cartons are sterilized with UVC light. Ice cream cups are cleaned in rinsing centers and the cold packs are refilled with cooling liquid harmless to people and the environment. This way, even Corona viruses are eliminated by up to 99.999% (log4) right before the eyes of the customer in numerous ice cream parlors.

UVC sterilization of the carton takes place in a sterilization cabinet. This process takes only a fraction of a second and has long been used in the sensitive area of children's or baby foods, where product hygiene and the importance of microbiological cleanliness of packaging and product quality have always been of decisive importance.

Goodbye "disposable ice cream cups."

Used deposit cups are returned vis-a-vis the deposit system (0,20€) - just as they were delivered - in the carton. They are then brought to the rinsing centers (using the lowest energy consumption) in an environmentally friendly cyclical system, eliminating additional trips and unnecessary CO2 emissions.

A good 6,000 GelatoPack ice cream cups are sold daily during the summer months. Calculated over the entire ice cream season, this means around 1 million saved "disposable ice cream cups" in the first business year alone. The amount of ice cream alone could fill over three thousand bathtubs. This amount is hard to imagine. However, it becomes very clear how much plastic or “disposable ice cream cups" are eliminated through the deposit system. We are talking about 31 tons.

Recycling

The biodegradable and reusable cold packs and ice cream cups are all made from renewable, plant-based raw materials such as corn by-products, which hardly differ from conventional plastic cups.

At the end of their lifecycle, the cups, and cold packs, which are sorted by type, are transported to the nearby recycling company in an equally efficient manner. The granulate obtained is used to produce new cups or other bio-based synthetic products. This way, we give our reusable cups and cold packs a second life.

Climate impact

The production of disposable ice cream cups consumed in Germany each year (excluding coffee-to-go cups) generates around 3,400 metric tons of CO2emissions. Added to this are the 555,000 tons of CO2emissions from ice cream parlor patrons who drive to the gelateria. This trip is no longer necessary, since bicycle delivery couriers can now deliver up to 18 ice cream cups at the same time on an optimized delivery route while wearing a backpack. World record!!! A decisive contribution to reducing city traffic and thus CO2emissions.

- "Having ice cream delivered is more environmentally friendly than having customers drive to the ice cream parlor in their cars, as calculated by American researchers. The consumers order and leave their car at home. This cuts the CO2 emissions that would otherwise occur by half." Source: Umweltdialog.de

- "Assuming that every second person drives by car (to the ice cream parlor), and the other half rides a bike or walks, the e-bike delivery service would still come off much better. Especially if you consider that the delivery service doesn’t usually deliver to just one customer but several customers at a time," explains expert Dr. Hyewon Seo, from the Federal Environment Agency.

1:0 for the environment - Thank you, GelatoPack

The GelatoPack cooler saves 96.66% of the environmentally harmful "disposable ice cream cups."

In addition to cardboard, large quantities of the plastic polyethylene are used for production of disposable cups. More than 100 tons of polyethylene are required for disposable cardboard made ice cream cups used in Germany each year. According to Bund-Sachsen-Anhalt https://www.bund-sachsen-anhalt.com/themen/gesellschaft-gestalten/nachhaltiger-konsum/oelwechsel-fakten-zu-erdoel-und-plastik/werden, around 2,400 tons of crude oil are squandered each year in the production of polyethylene coatings for disposable cardboard ice cream cups, as well as for disposable polystyrene cups and lids.